At Dymicron®, we’re revolutionizing the medical device joint replacement market by redefining the definition of performance and reliability with cutting-edge Adymite™, our polycrystalline diamond technology. Adymite is engineered for durability, reliability and superior performance. This technology pushes the boundaries of what’s possible in joint replacement.

Dymicron was founded on a single vision to revolutionize precision products with the world’s most advanced material—Adymite, polycrystalline diamond. Our journey began with a focus on harnessing the unmatched properties of Adymite to deliver superior performance, durability, and reliability for industries that demand excellence and longevity. Adymite is a synthetic material known for its extreme hardness and wear resistance, making it the perfect choice for applications that require reliability, durability and performance.

With Dymicron’s patented process, we’ve unlocked the potential of Adymite to create products that outperform traditional joint replacement materials and designs with proven clinical performance, longevity in use, and virtually no wear debris.

Since our inception, Dymicron has been at the forefront of Adymite innovation. From our early prototypes to the launch of our flagship product, we’ve continuously pushed the boundaries of material science to deliver solutions that drive clinically superior performance.

Discover the impact of Adymite technology

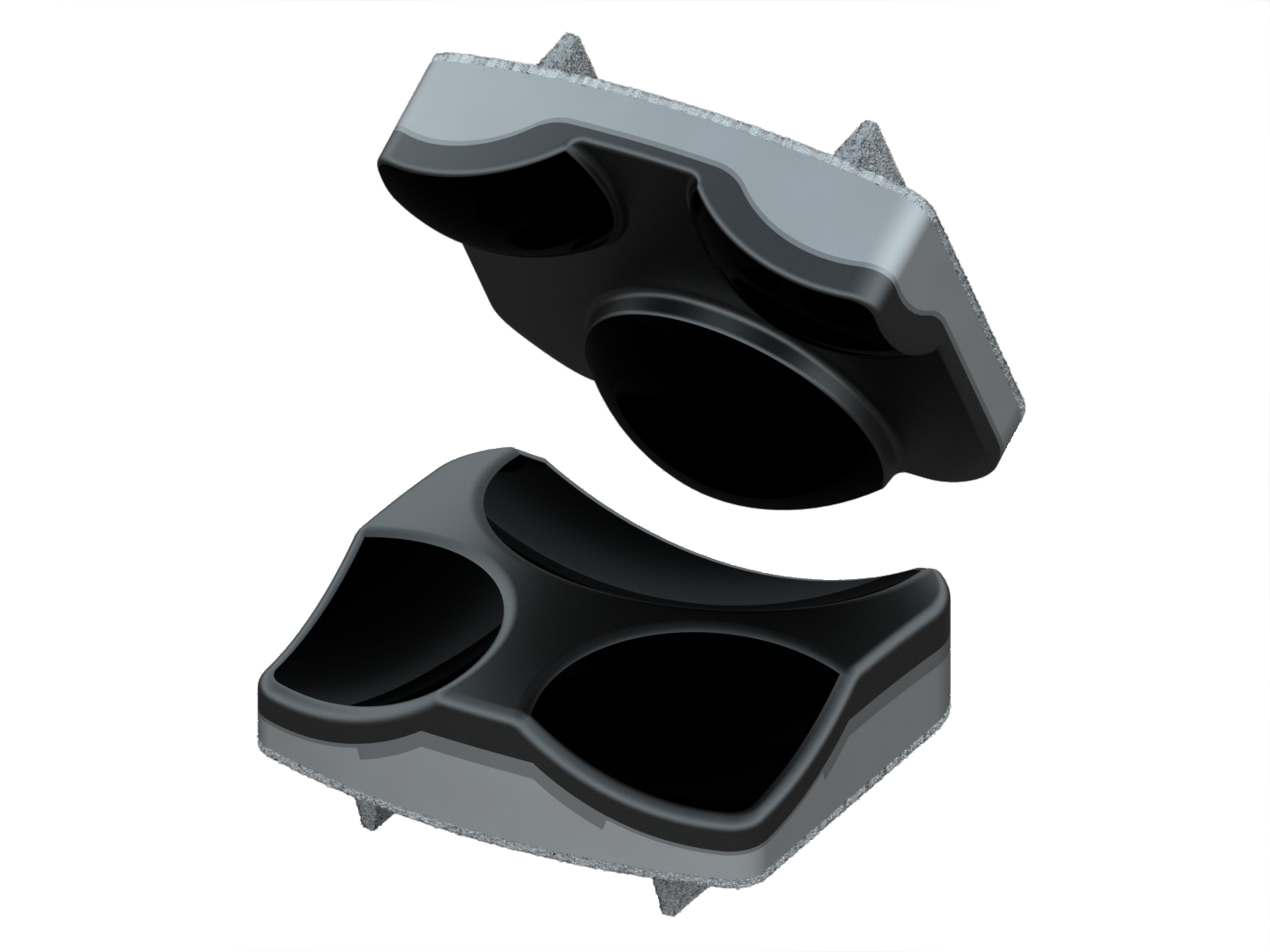

Triadyme–C is Dymicron’s flagship product. Triadyme-C is designed to deliver unprecedented reliability, durability and performance in cervical total disc replacement surgical procedures. Powered by our advanced Adymite technology, the Triadyme–C, artificial cervical disc, is engineered to mimic natural spinal motion, virtually eliminate wear debris, increase device longevity and provide superior performance to deliver excellent, long-term clinical results.

It’s a very, very safe material, which means that even though it’s manmade polycrystalline diamond, it’s basically carbon. Our bodies are made of 18% carbon, and I wouldn’t expect anybody’s body to respond to this material. There have been materials out there that we see the patient’s body respond to, but this is not one of them.

The unique tri-lobe design that we see within the Triadyme-C is another key parameter that provides us with a very natural motion pattern that mimics very much what we see in the natural disc for the patients.

Diamond is an extraordinary biomaterial. It’s extremely biocompatible. [The] body has virtually no reaction to diamond as a bulk material or as a particulate…It has the lowest coefficient of friction. As a bearing surface, it has the lowest degree of contact wear. If you could make bearings for prosthetic devices out of diamond, the prospect of creating a hip or a spinal device that never wore out becomes a possibility.

February 12, 2026

Read More on LinkedIn

January 29, 2026

Read More on LinkedIn

January 15, 2026

Read More on LinkedInSign up to discover the latest news about Dymicron and our proprietary polycrystalline diamond technology–Adymite. Adymite is redefining performance and reliability in spinal disc replacement, including delivering unmatched durability and excellent long-term outcomes for patients.